BEAM ON

The electron beam process uses high-energy electrons from electrical current, accelerated to near light speed. These electrons are focused and scanned to form a curtain, through which products pass at a controlled speed to receive a precise radiation dose, inactivating microorganisms or altering polymer structures permanently.

Electron Beam Application

Sterilization

Electron beam sterilization is routinely used in many applications with a high level of customer satisfaction. The e-beam radiation inactivates microorganisms by causing microbial death. Electron beam sterilization is supported by the internationally recognized consensus standard, ISO 11137, which describes the approach to validating a process to achieve a defined sterility assurance level (SAL). Commercial e-beam sterilized products such as:

- Surgical gloves

- Catheters

- Drug containers

- Sterilized panty

- Syringes

- Surgical gown

- Bandages

- Sponges

- Labware

Polymer Crosslinking & Material Modification

Electron beam crosslinking process improves product strength, thermal resistance, friction resistance, abrasion resistance, impact resistance, and electrical resistance properties and changes or enhances many other material properties.

- Plastic tubing and molded parts

- Jacketed wire and cable products

Food Irradiation

Electron beam process reduces the microbial load in human food, pet treats and animal feed, and supplements. To meet your microbial reduction purpose, Electron beam processing kills microorganisms through a non-invasive process that penetrates several types of packaging. There are no residues left on the product. To keep consumers safe from illness by reducing yeast, mold, fungi, bacteria, and any pathogens in product.

- Dry food and dehydrated ingredients

- Spices & Herbs

- Pet treats and animal feed

Benefits

-

Fast processing times

Fast processing -

Considerably less oxidative damage to the product

Considerably less -

Improved supply chain efficiencies

Fast processing times -

No chemical residuals or induced radioactivity remain on processed products

No chemical residuals -

Reduced color change in any present polymers

Reduced color change -

Suitable especially for food or heat-sensitive products

Suitable especially

Improved supply chain efficiencies

Electron beam technology in the supply chain enhances flexibility, reduces costs, and improves the overall quality of products and processes

Purposes of Irradiation

-

To Inhibit of sprouting

To Inhibit of sprouting -

To prolong shelf life

To prolong shelf life -

To delay ripening

To delay ripening -

To reduce microorganisms and eliminate disease-causing microorganisms

Microorganisms and eliminate -

To control insect disinfestation

To control insect disinfestation -

To reduce parasite

To reduce parasite -

To sterilize medical devices

To sterilize medical devices -

To material modification

To material modification

Process of Irradiation

Check-in Package

Dosimetry

Irradiation

Quality Control

Check-out Package

Certified Standards

ISO 9001 Certified

Quality Management System (QMS)

Our E-beam irradiation sterilization services are ISO 9001 certified by United Registrar of Systems (Thailand) Co., Ltd., an ISO certification body registered in England. With this globally recognized quality management standard certification, we ensure that our customers consistently receive high-quality products and services that meet international standards.

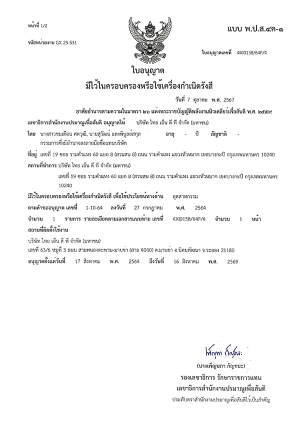

Radiator license to possess and utilize from OAP

This license is issued by the Office of Atoms for Peace (OAP), Thailand's regulatory authority responsible for overseeing the safe use of radiation and nuclear energy. The license permits the possession and utilization of radiation-emitting equipment, such as electron beam machines, under strict compliance with safety regulations.

It ensures that our facility meets all required safety standards for handling and operating radiators, protecting both our employees and the environment while delivering reliable irradiation services to our clients.

USFDA

Our Electron Beam irradiation service is officially recognized and approved by the U.S. Food and Drug Administration (FDA).

We are dedicated to delivering cutting-edge sterilization solutions that meet the highest quality and safety standards, as validated by FDA approval.

With our FDA-certified process, you can confidently introduce your regulated products to the U.S. market, ensuring compliance with strict FDA requirements. This opens the door to new business opportunities, strengthens customer confidence, and enhances your brand's reputation.