NDT and Inspection services as well as engineering consulting and technical development services to a broad range of industries for over 38 years.

Asset Integrity Management

Reduce risk with cost-effective solutions.

Integrity Management

We develop software solution for integrity and management plans to inspection methods identify and optimum inspection frequency.

Online Corrosion Monitoring

Online corrosion monitoring brings Corrosion Management to life. Enabling operators to quantify internal corrosion processes in on-line and real-time mode

On-time and accurate detection of uniform and localized metal corrosion is fundamental for safe and reliable operation of any process plant and optimization Known values of corrosion rate allow prediction of the remaining service life for process piping or equipment, and furthermore help establishing proper preventive inspection and maintenance activities.

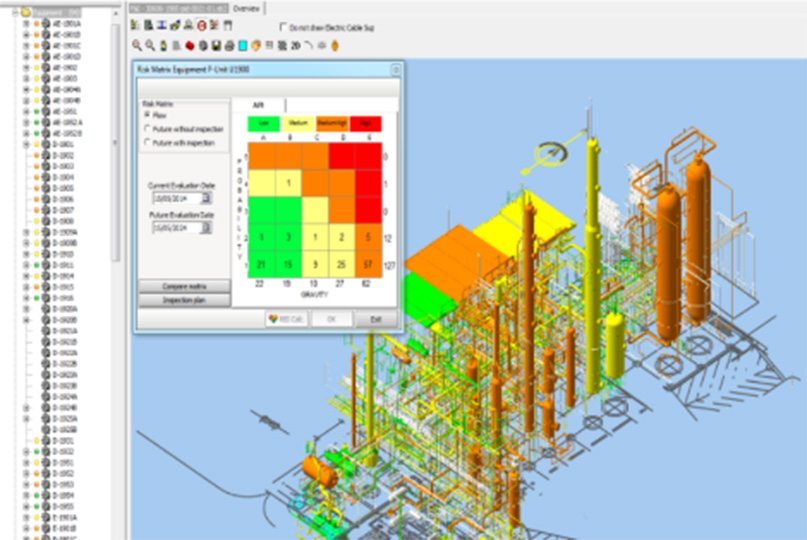

Risk Base Assessment & Implementation (RBI)

Risk-based inspection (RBI) technology uses qualitative and quantitative methodology when applied to safety-critical equipment in the onshore refinery, petrochemical and gas processing industries.

This risk-based inspection system allows you to plan accordingly with the help of interactive matrices to provide a safe, healthy work environment.

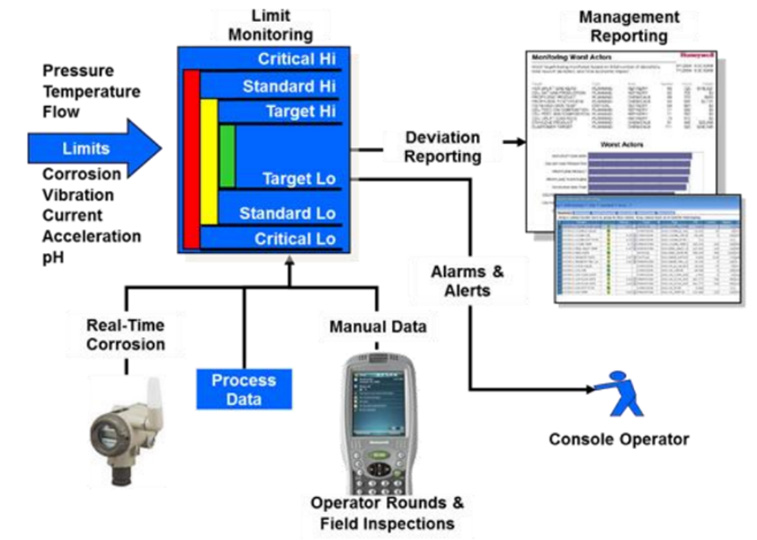

Real time Integrity Operating Window (IOW)

Modern corrosion management systems incorporate several elements from basic corrosion engineering through corrosion prediction and modeling software up to sophisticated solutions which accommodates Risk Based Inspection (RBI), process data, alarm management and on-line corrosion measurements.

Integrity Operating Windows (IOW), as formulated by the American Petroleum Institute in their Recommended Practice 584, plays a key-role in any modern asset integrity management program. A generic approach to integrate Integrity Operating Windows within a process-corrosion-alarm system is presented In Figure 1

The process for establishing the limits of key-operating parameters and their criticality is based solely on their known or predicted impact on corrosion and degradation rates.

The actual corrosion rates should be visible to the process and corrosion engineers for validating the IOW limits. This is done by comparing the actual corrosion rates with the expected levels of material degradation when the limits were set.

Integrity Management Software Solution

In order to maximize productivity, your static equipment in the Oil & Gas industry need to be maintained regularly. Integrity Management Software Solution can help end users managed effectively to control costs and risks ,including your assets to ensure productivity, reliability and safety.

Fitness for Service (FFS)

Instituting an FFS program as part of a reliability management program helps reduce challenges related to budget acquisition and assessment completion time. Preparing for potential assessment before a shutdown can save time collecting the data required to complete the assessment.

Including fitness-for-service technology and assessment capabilities as part of regular maintenance programs can save time and costs during critical outages. Ensuring that these capabilities exist as part of a maintenance program budget can prevent the extension of shutdowns and potentially avoid unplanned shutdowns.

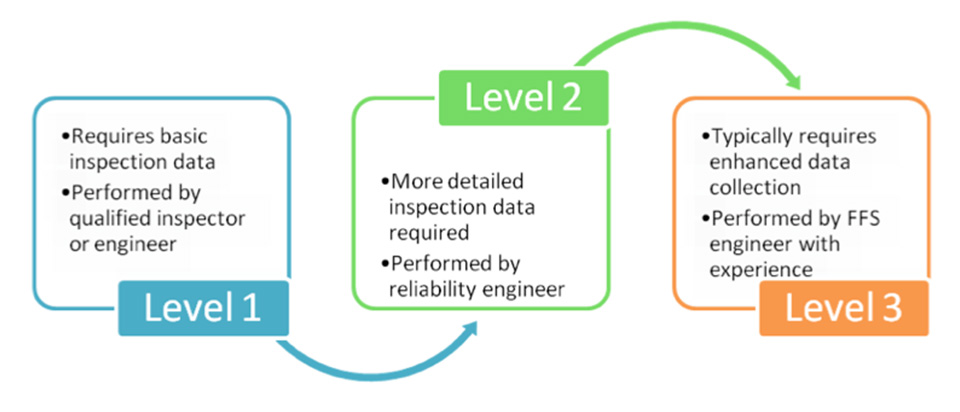

FFS assessments usually require a standard list of information including original design conditions, materials of construction, and operation and maintenance history. While this information is part of standard record keeping at many facilities, it is not always readily available. There are three levels of assessment, is presented In Figure 2, all of which are progressive

Level 1 Level 1 assessments require the least amount of data and experience. This type of assessment usually uses tables and screening curves and requires few computations. This means the computations can be quite conservative, similar to design code calculations. This level of inspection tends to take less time than the other two.

Level 2 If a Level 1 assessment on a piece of equipment does not meet acceptance criteria, a Level 2 assessment can be performed. A Level 2 assessment requires significantly more involved computations to replace the simple, conservative computations that make up the Level 1 assessment. The benefit is that fewer conservative calculations may lead to a better outcome, but the computations are complex enough that FFS software is often required.

Level 3 Generally, Level 2 assessment criteria are met and the equipment can be returned to service. But, In severe cases, a Level 3 assessment may be required. Compared to the previous two levels, a Level 3 assessment requires more detailed data and a considerable amount of operational experience on the part of the inspector. Because of errors that can occur due to using the more advanced equipment Level 3 analysis are rarely conducted.